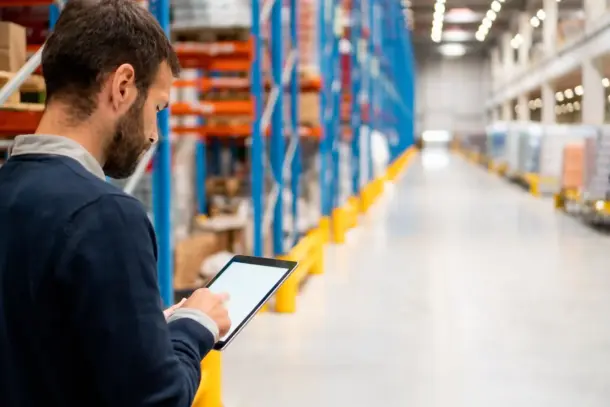

Factory planning with LOGSOL: Sustainable solutions for your production

Through comprehensive factory planning, we pursue the goal of making your company more competitive. Whether you want to optimize an existing production facility or build a new factory: Our focus is on ensuring that you can work there with maximum efficiency and flexibility in the future.

Your advantages of our factory planning: Why LOGSOL is the perfect choice!

We offer you comprehensive expertise in the field of factory planning and provide you with holistic support. Starting with concept planning and the preparation of tenders through to implementation, we are at your side. We always keep an eye on your long-term corporate goals and costs.

Plant structure planning

We organize the functional areas of the factory optimally according to future requirements and design future-proof processes.

- Plant layout: Overarching structure of production, administration and logistics areas

- Plant logistics: Design of traffic areas, loading points and parking spaces

- Infrastructure: supply with relevant media, connection to public infrastructure, waste disposal

Layout planning & process planning

We plan resilient solutions so that our concepts function reliably even in the event of unplanned developments.

- Processes: Planning of target processes and information flows along the value chain

- Dimensioning: needs-based calculations of the type and number of machines, systems and equipment required

- Layout design: design of the physical layout of the factory, including the placement of machines, workstations and logistics and social areas

Material flow planning & logistics planning

We create a smooth production flow for you within the factory, including material procurement, storage, transportation and distribution.

- Supply chain: seamless integration of the supply chain to ensure efficient management of materials and products

- Logistics planning: storage, transportation and hiring of materials using modern technologies and automation

Production planning

Our team of experts optimizes your resource utilization for optimal throughput times and for the ideal allocation of your capacities.

- Capacity planning: Determining the necessary capacity, taking into account production equipment, labor and other resources to meet demand

- Production control: Definition of production processes and schedules to ensure that deadlines are met

- Quality assurance: defining and maintaining standards in production

Working environments

We design modern working environments so that you can react flexibly to changes in production, society and the environment.

- Ergonomic workplace design: Minimizing physical strain to increase productivity and well-being

- Robotics/human-machine interaction: Smooth interaction between your employees and technologies

- Health and safety: Creating a safe working environment that prevents accidents and work-related illnesses

Factory planning from LOGSOL with added value for your company

Planning good use of space

Maximize your productivity

Ergonomic design of working conditions

Optimizing costs and increasing profitability

Sustainable design of your production

Digital factory planning

LOGSOL relies on innovative software solutions for 2D and 3D visualization in factory planning and logistics planning. We use these tools to analyse, plan, optimize, evaluate and visualize production facilities and factories. 360° images and 3D laser scans are carried out for digital stocktaking. Benefit from advanced data acquisition and save costs in further planning steps.

Building Information Modeling (BIM)

Using the BIM method, we identify and solve problems on construction sites even before the first sod is turned. The BIM model is the digital twin of the construction project and contains all relevant information about its life cycle. This provides a transparent overview of all project data and steps for efficient planning, construction, coordination and management.

Efficient brownfield planning: central logistics processes in the existing building

Brownfield planning of an existing building for the centralization of logistics processes from incoming goods to supply logistics and outgoing goodsRead more

Site planning and implementation

Development of an existing logistics location to integrate additional product ranges from other locations of the SSV-Kroschke GroupRead more

Logistics concept for hospital supply

Master planning of hospital logistics for the transformation of an urban hospital of the highest care class into a university hospital with a future-oriented campusRead more

Strategic depot network optimization & implementation: logistical concept study with PMO support

Consulting on the development of logistical concept studies to optimize a Germany-wide depot network - including support for the preferred solution as part of project management (PMO)Read more

SachsenEnergie SAP S/4HANA EWM preliminary project

Implementation of an SAP pre-project with the aim of drawing up specifications and a preliminary decision on the implemented SAP EWM variantRead more

Production simulation at B. Braun

Simulation of the entire production at the site to investigate various operating scenarios under the premise of maximizing output.Read more

Take the first step towards improving your processes with professional factory planning!

I will be happy to answer any questions you may have about factory planning!

Here you can find our privacy policy